Construction of 3-phase induction motor

Constitution of 3-phase induction motor

• Construction of 3-Phase Induction Motor:

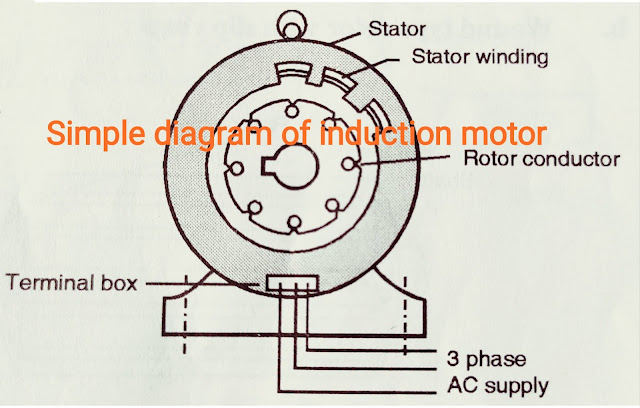

There are two main parts of a 3-phase induction motor

1.Stator

2.Rotor.

1) Stator:

- As the name suggests,it is a stationary part of the motor.This part is made or silicon steel stampings(i.e.thin sheets).The stampings are slotted.

- When complete stator is assembled,the through slots are formed on the inner side of the stator.The slots may be open type,semi-open type or closed type.In these slots,a 3-phase winding (made of super enamcled copper)is accommodated.This winding may be star or delta connected. Three ends of this coil are brought to the terminal box where a three-phase supply can be delivered.

- The stator windings, stator and the A.C. supply connected to the stator winding is shown in the fig.

2) Rotor:

Here two types of induction motors. That are depend on the construction of the rotor.

A) Squirrel cage type

B) Wound rotor type

A) Squirrel cage type rotor:

- This is the simple and most rugged construction.The rotor consists of a cylindrical laminated core with its skewed rotor slots.

- The rotor conductors there are thick copper bars, it is placed in that slots and that are brazed or welded to and rings. So, the rotor conductors are permanently short-circuited. In results,it is not possible to add any external resistance in the rotor circuit.

- The rotor body is made from silicon steel stampings.The construction of the rotor looks like a cage of “squirrel”and it is called as “squirrel cage type motor”.

B) Wound type rotor with slip rings:

- In this type of induction motor,the rotor is wound for the same number of poles as that on the stator.The rotor is made up of laminations with slots on the outer periphery in which a 3-phase rotor winding is placed.The three phases are starred internally.The remaining three terminals are brought out and connected to the slip-rings mounted on the shaft.

- The slip-rings are made up of copper or phosphor bronze and there are three brushes resting on them.External connections to additional resistances are done at the brushes.

- When operating under normal conditions, the slip rings are driven by a metal collar that pushes along the shaft and raises the brush from the slip ring to reduce friction loss and wear Taken.

- As a regular 3-phase winding is used for rotor,this type of is called as"phase wound rotor type”.It is also called as“slip-ring type"because slip-rings are used.

Comments

Post a Comment