Design of Stator

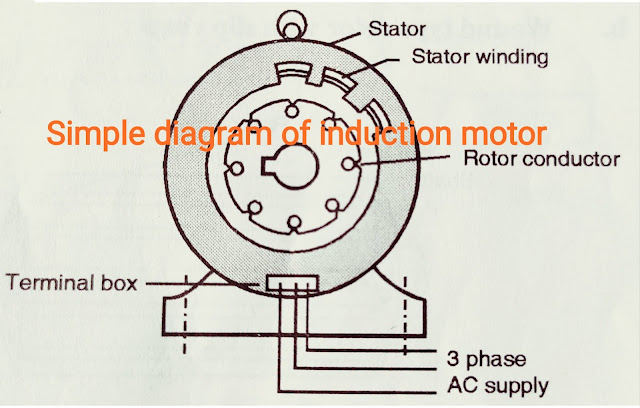

Design of Stator 1). Stator winding:- Generally two types of winding are commonly used for stator of three phase induction motor. (a) Single layer much winding is used for small motors with small number of slots. It is housed in semienclosed slots. (B) Double layer lap winding with diamond shaped coils is used for medium size motors. It is housed in open slots. As per the temperature class (class E, B, F etc.) impregnated insulaaon is used. The three phases of stator windings can be connected in either star or delta depending upon the starting method employed. The squirrel cage induction motors are usually started by star delta starter and hence the stator is designed for delta connection, with six leads for connection to stator. For slip ring induction motor I. e. wound rotor construction motors, starting method used is resistance in rotor circuit, so stator can be designed either for star or delta as per require...